Irabha yerabha ye-raller cnc grinding

Ingcaciso yeMveliso

1. I-CNC ye-CNC yokusebenza yabasebenzi.

2. Inkqubo yakutshanje inokusebenza ngokulula ngokulula izikimu ezingama-35 kumhlaba werabha yerabha, equka ukusikwa, ukugaya, i-groovings kunye nokudibanisa.

I-3. Ukude kwingxaki yokudubula kwengxaki inokukhethwa.

I-4. I-Angle ye-Angle eguqukayo yintloko inokukhethwa.

5. Ukuba nayo yonke imisebenzi ye-PSM yethu ye-PSM Gurinding egalelekayo.

1) Izixhobo ezisemgangathweni zoluhlu lwe-PSM zibandakanya:

I-AA ijikeleze imigudu epheleleyo

I-B.MotorTARCET

I-C.varing Isantya sokuhamba kunye ne-spindle drives

D.Front kwaye ungenise ngasemva kweetafile zenqwelwana ngentloko

I-EA Trepf Drive Grinding intloko ifakwe ngasemva

2) Yenzelwe ngokukodwa ukutshintsha indlela yenkqubo ye-roller yemveli.

I-3) Iitheyibhile ezimbini zenqwelomoya ezihlanganisiweyo ezihlanganisene ukuze ziqinisekise ngokuchanekileyo ukusebenza kunye nokuzinza okusebenzayo.

4) i-max. Isantya somgca wentloko yokugaya singaphezulu kwe-90m / s. Ukusebenza kakuhle kuyandiswa kwaye ubungakanani bejometri kuqinisekisiwe.

5) Isixhobo sokulinganisa esihlanganiseneyo sijonga idatha yokuqhubela phambili kwaye ibonelela ngoncedo olusebenzayo lokulawula ubungakanani be-graising unokuphucula xa kuceliwe.

I-6) ikwanakho ukufumanisa ukwanda kokulungiswa kweengqengqele zerabha ezikhethekileyo.

| Igama | Imodeli | Intsimbi / irabha | Dia. | Leng | Ubunzima | ||

| Irabha r umatshini wokugaya | I-PSM-4020 / D | Hayi / ewe | I-400 | 2000 | I-500 | ||

| Irabha r umatshini wokugaya | I-PSM-6030 / D | Hayi / ewe | I-600 | I-4000 | 2000 | ||

| Irabha r umatshini wokugaya | I-PSM-8040 / D | Hayi / ewe | I-800 | I-4000 | I-5000 | ||

| Irabha r umatshini wokugaya | I-PSM-1250 / D | Hayi / ewe | I-1000 | I-6000 | I-6000 | ||

| Irabha r umatshini wokugaya | I-PSM-1460 / D | Hayi / ewe | 1200 | I-8000 | I-8000 | ||

| Irabha r umatshini wokugaya | I-PSM-Medibani | Hayi / ewe | ngokuzithandela | ngokuzithandela | ngokuzithandela | ||

| Amagqabantshintshi | D: Ikhompyuter yamashishini T: Isikrini sokuchukumisa | ||||||

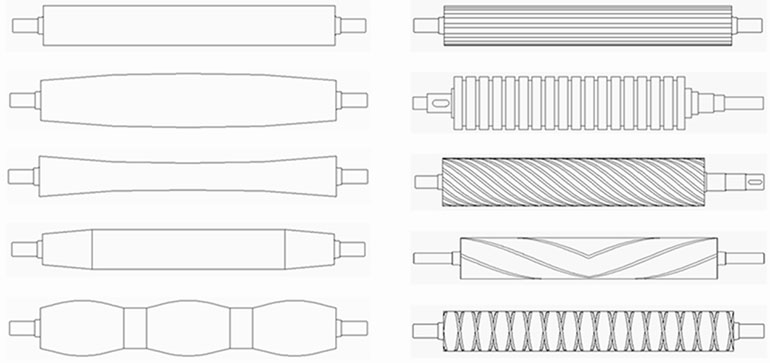

Iprofayile yeRoller

Inkqubo inomsebenzi wokulungisa wonke umjikelo, kunye nezikim zokulungisa ezingama-35:

Ineentlobo ngeentlobo zemisebenzi yokusika, iintlobo ezi-5 zemisebenzi ye-GARDE YOKUGQIBELA

Isicelo

Isiseko kuMatshini oGqibeleleyo we-PSM GARGE, ungcelele ochungechusiweyo we-PSM-CNC uphuhliswa ngokutshintsha uhlobo lwenkqubo eqhutywa kunye nenkqubo yokulawula. Inkqubo ye-CNC yesoftware elawulwa yidijithali yokuqhubela phambili. UJinan World Ruble Roll Rill Inkampani kunye namaziko ophando lwenzululwazi kuphuhlise isoftware. Iimpawu zayo zomsebenzi zomsebenzi zezona zinto zibalulekileyo phakathi kweShishini loMatshini. Ngenxa yomjikelo wonke wenkqubo, unokwenza phantse yonke iprofayili yeengqubela. Umzekelo, isithsaba se-parabolic kunye ne-coyine, i-cosine yesithsaba kunye ne-cocauve, cone, i-cone, i-herringbone, i-groove, ethe tye kunye nezinye iindlela.

Iinkonzo

1. Inkonzo yokufaka indawo inokukhethwa.

I-2. Inkonzo yolondolozo ebomini ide.

I-3. Inkxaso ye-Intanethi isebenza.

4. Iifayile zobugcisa ziya kubonelelwa.

5. Inkonzo yoqeqesho inokubonelelwa.

I-6. I-Spare Spirement kunye nenkonzo yokulungisa inokunikezelwa.